PretreatmentĬommonly treat skins/bones with acid, alkaline, or maybe enzyme to release collagen from raw materials. The manufacturing of gelatin is generally with two principal processes: 1. It is mainly used as calcium and phosphorus supplements in feed and can be easily digested and absorbed by livestock and poultry. It cannot be produced from noncollagen parts of animals, such as horns, horse hoofs.īy the way, dicalcium phosphate is a major by-product in the production process of gelatin. Also, animal raw materials from epidemic areas and with infectious diseases cannot be used.

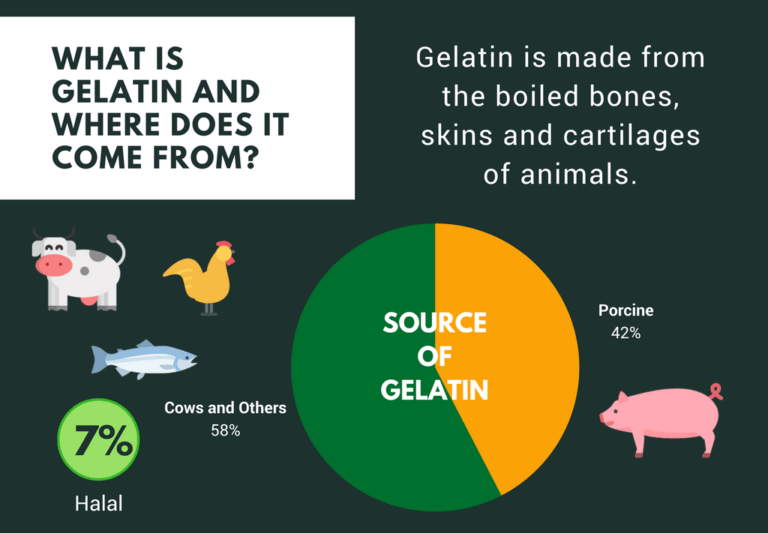

Fresh, strictly quarantined animal bones or skins that have not undergone any chemical treatment are required. It is strict in selecting raw materials for producing edible gelatin. The edible gelatin is high in protein, low in heavy metal and other impurities. Gelatin is made from the skin, bone, cartilage, and other connective tissue rich in collagen from animals (pig, beef, fish, chicken, etc.).

#WHERE DOES GELATIN COME FROM SKIN#

Chicken gelatinĬhicken gelatin has a high gel strength, commonly made from chicken skin or bones, which is rich in collagen. The higher the content of imino acids in gelatin, the better the gel properties. Generally speaking, compared with mammal sources, gelatin derived from aquatic animals has poor gel properties is mainly due to its much lower imino acid content (proline and hydroxyproline), especially from cold-water fish. Meanwhile, fish gelatin has a more or less fishy smell, and this smell limits its application. So fish gelatin is suitable to be used in desserts which needs a low melting point and quick flavor release in the mouth. For example, fish gelatin confectionery melts faster at a higher temperature and releases its flavor more quickly in your mouth, which gives you a flavorful feeling. Without the risks of disease that would happen in bovine and porcine.Ĭompared with pig and bovine gelatin, fish gelatin has lower molecular weight, lower gel strength and lower melting temperature, resulting in lower market demand.īut this is a unique property in some specific applications.Acceptable for all religions and cultures and is almost suitable for all consumers.With the similar functionalities of gelling, foaming, emulsifying and binding, fish gelatin can be used as a substitute for bovine and porcine gelatin with the following two advantages: These fish species include cold-water fish such as alaska cod, pacific cod, green pollock, and salmon and warm water fish such as tilapia, grass carp, squid, and tuna. skin, bones, scales, and fins) can be used to produce fish gelatin. It is made from bovine hides or bones, which can be accepted as kosher and halal, complies with the law of Muslims and Jews, but not vegan friendly. However, its applications are restricted in Islamic countries as it is not halal.

Pigskin based one is the most commercially used gelatin in the world owing to its cheaper price. However, with religious or ethical reasons from pig and beef gelatin, as well as diseases such as BSE (Bovine spongiform encephalopathy) and foot-and-mouth disease, fish gelatin can be a replacement. fish) is only produced and applied on a small scale. The top four commercial sources are mainly porcine skin/bone and bovine hide/bone. Compare with Collagen and Hydrolyzed gelatin.Gelatin is often used as a gelling agent, stabilizer, emulsifier, thickener, and clarifier in food and capsules. This phenomenon is caused by gelatin, which is produced during the cooking process. You may have cooked the bone broth at home, and noticed the surface of the broth looks like a clear jelly texture after the boiled bone soup cools down. Gelatin (or gelatine) is a protein made from the partial hydrolysis of collagen, which is generally derived from the skins and bones of porcine (pork), bovine (beef or cattle), and fish.

0 kommentar(er)

0 kommentar(er)